- Home Page

- Company Profile

-

Our Products

- Magnetic Separators

- Single Drum Magnetic Separator

- Wet Drum Magnetic Separator

- Inline Magnetic Separator

- Coolant Separator

- Double Drum Magnetic Separator

- Drum Type Magnetic Separator

- Pipe Line Magnetic Separator

- Magnetic Drum Separator

- Low Intensity Magnetic Separator

- Magnetic Roller Separator

- Overband Magnetic Separator

- Magnetic Equipments

- Permanent Magnetic Equipment

- Vibrating Equipment

- Industrial Magnetic Pulley

- Vibrating Screen Machine

- Magnetic Lifter

- Electromagnetic Vibrator

- Gyro Sifter

- Magnetic Separators

- Extra Links

- Contact Us

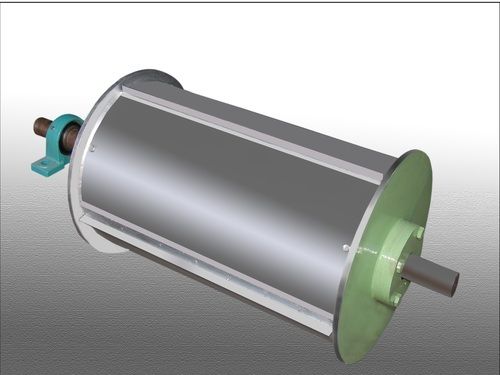

Magnetic Pulley

60000 INR/Piece

Product Details:

- Length 2-6 Foot (ft)

- Size 500-4500

- Color yellow

- Height 3-8 Foot (ft)

- Weight 230 Kilograms (kg)

- Width 500-1500 Millimeter (mm)

- Click to View more

X

Magnetic Pulley Price And Quantity

- 60000 INR/Piece

- 1 Piece

Magnetic Pulley Product Specifications

- 230 Kilograms (kg)

- 500-4500

- 2-6 Foot (ft)

- 3-8 Foot (ft)

- 500-1500 Millimeter (mm)

- yellow

Magnetic Pulley Trade Information

- Ahemdabad

- Cash in Advance (CID) Cheque

- 100 Piece Per Month

- 1 Week

- As per standard

- Australia Western Europe Africa Central America Middle East South America Asia Eastern Europe North America

- All India

- ISO 9001:2008

Product Description

Accredited with ISO 9001: 2008 certification, we are manufacturing and supplying a wide array of Magnetic Pulley. The offered pulley is used in conveyor machine for easy handling of materials.Our skilled professionals manufacture this pulley as per the international market norms by making use of outstanding quality components with the help of innovative techniques. Moreover, our clients can purchase this Magnetic Pulley at the most economical prices from us.

Technical Details of Magnetic Pulley:

1) Material Of Construction : Stainless Steel(SS)

2) Diameter : 200 - 380mm

3) Rust Resistance : Yes

4) Length : 600 - 2000 mm

Products Features:

1) Rugged design

2) Rust proof

3) Superior surface finish

4) Accurate dimension

5) Compact Design

6) High Operational Fluency

7) Energy Efficient

8) Excellent Performance

9) Low Maintenance

10) High Strength

11) Robustness

12) Noiseless Processing

Products Specification:

1) It can be made of any shape and size.

2) Can be installed over brand / underneath the passing material.

3) Best performance is given when the material is actually striking it.

4) Can be used all type of mills, textiles, chemicals, glass, ceramics, in facts the is very long

Further Details:

At the conveyor belt, drive pulley is replaced by magnetic head pulley at the end. Magnetic pulley is developed in different sizes to suit a wide variety of conveyor belt types. As the material flows, the magnetic head roller extracts the iron particles and transfer them to belt's underside, from where the particles are removed and collected. This kind of permanent magnet is outfitted with high intensity Nd - Feb rare earth magnet and An-Isotropic hard ferrite magnet. This system does not require any power supply. For buyers, magnetic system is accessible in two types:

1) With Longitudinal polar field distribution to be used with iron contamination of lower levels as well as thin material layers.

2) With lateral polar field distribution to be used with larger iron particles and solid material thickness.

Once the magnetic pullet is separated from the belt, the magnetism dissipates and the contamination collected falls from under the belt into a receptacle.

Enter Buying Requirement Details